Our detailed assessment fully explores different types of lifts, unlocking their average costs, strengths, and challenges. In the Indian market, where home elevators prices vary based on type, navigating the complexities becomes crucial.

Different Types of Lifts for Home

We aim to elevate your decision-making process, provide personalized guidance, and tailor-made solutions aligned with your vertical transportation needs. Trust us to decode the elevator realm and unmask the complexities, illuminating the decision-making landscape. Read this article today to unravel the mysteries of elevator selection and discover the perfect solution for you. Additionally, our professional team is here to assist you every step of the way.

Different Types of Lifts Overview

- Lift Technology Overview

- Different Types of Lifts Pros and Cons

- Traction Elevators Pros and Cons

- Hydraulic Lift Pros and Cons

- Pneumatic Vacuum Lift Pros and Cons

- Machine Room-Less (MRL) Lift Pros, Cons

- Cable-driven Lift Pros and Cons

- Counterweight Lift Pros and Cons

- Smart Elevators Pros and Cons

- Green or Energy-Efficient Elevators Pros, Cons

- Freight Elevators Pros and Cons

- Home Lifts Pros and Cons

- Glass Elevators Pros and Cons

- Double-Decker Elevators Pros and Cons

- Different Types of Lift Price in India

- Conclusion

Lift Technology Overview

How Traction Elevators Work

Geared Traction Elevators utilize a gearbox to regulate the movement of the elevator car, while Gearless Traction Elevators feature a gearless traction machine, ensuring a smoother and quieter ride.

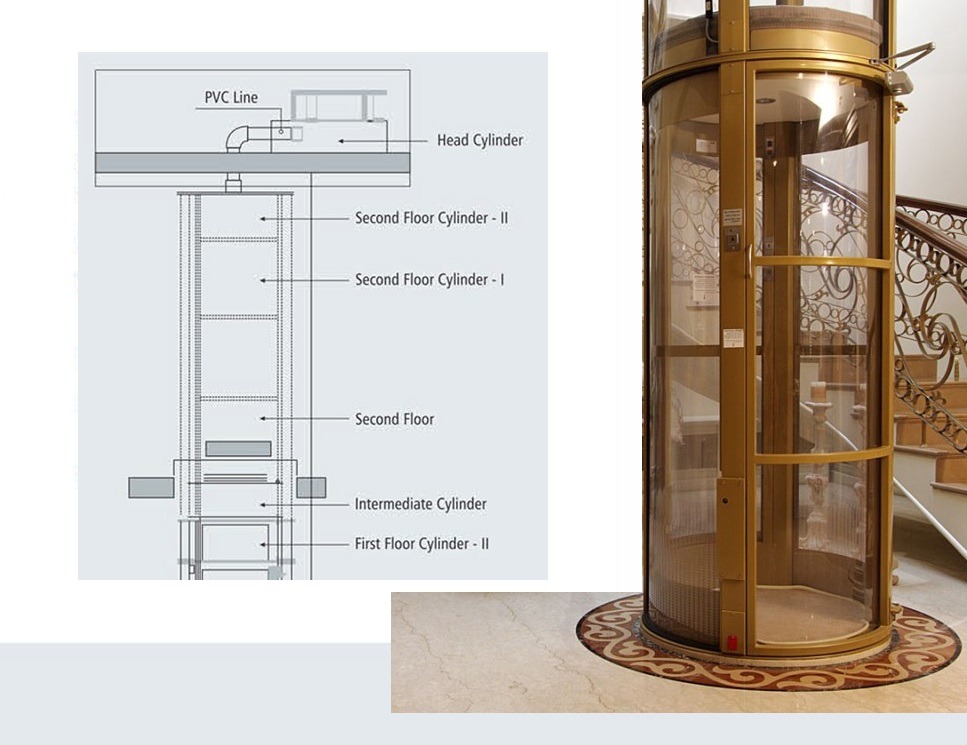

How Hydraulic Lift Works

These type lifts use a hydraulic fluid when the piston is moved, the elevator car moves the top and bottom of the building based on piston motion. It has less capacity to move tall buildings. So, They are suitable for low to mid-rise buildings.

How Pneumatic Vacuum Elevator Work

These types of lifts use air pressure changes to move the elevator car. They are often sleek and transparent, offering a unique design.

How Machine Room-Less (MRL) Elevators Work

MRL elevators integrate most of the components, such as the motor, inverter, and control system, into the shaft, eliminating the need for a separate machine room.

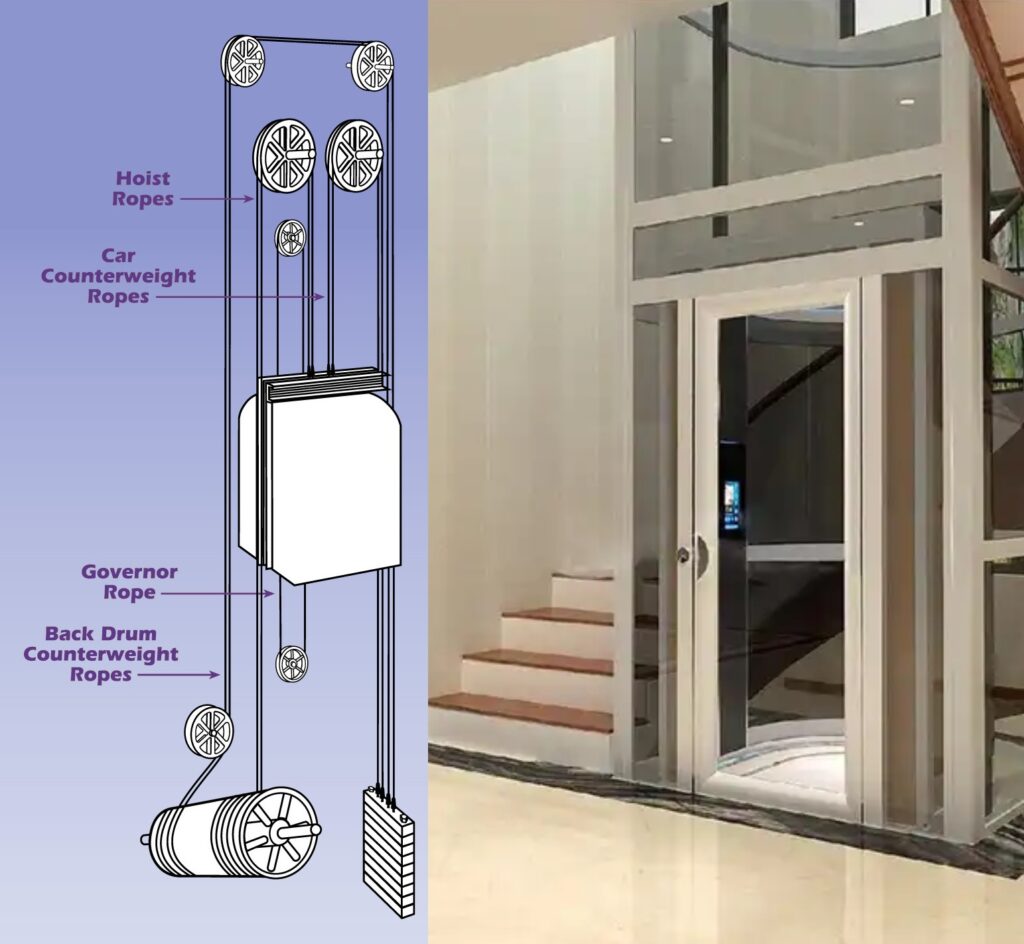

How Cable-driven Lifts Work

These type of elevators use a system of cables and pulleys to move the car. They may be either gearless or geared.

How Counterweight Elevator Works

These elevators use a counterweight to balance the load, making them more energy-efficient.

How Smart Elevator Work

These type of elevators often come with smart features, such as touchless controls, destination dispatch systems, and predictive maintenance.

How Home Lift Work

These type of compact elevators designed for residential use, providing accessibility between floors in private homes.

How Freight Elevators Work

These type is specifically designed for the transportation of goods and heavy items within a building.

How Green or Energy-Efficient Elevator Works

These type of Elevators are designed with energy-saving features. Which like as regenerative drives & LED lighting.

How Glass Lift Works

These type of lifts with transparent walls or floors, offering a scenic view as passengers travel between floors.

How Double-Decker Elevators Work

These elevators have two stacked cabins, allowing for the transportation of passengers on two separate levels simultaneously.

Different types of lifts Pros and Cons

Here’s a breakdown advantages and potential difficulties of different types of elevators, along with their capacity of load it withstand:

Traction Elevators Pros and Cons

Pros:

- Smooth and quiet operation.

- Suitable for high-rise buildings.

- Many manufacturers offer customization options for interior finishes, lighting, and cabin size.

Cons:

- Difficulty: Higher initial cost and maintenance requirements. Explanation: Geared traction elevators may require more maintenance due to the gearbox, and gearless traction elevators can have a higher upfront cost.

Technology: Electric traction machines with ropes or belts.

Typically, Traction Elevators have a loading capacity ranging from approximately 454 to 2,268 kilograms (about 4 to 23 passengers), depending on the specific model and design.

Hydraulic Lift Pros and Cons

Pros:

- Cost-effective for low to mid-rise buildings.

- Simple and reliable design.

- Customization options often include cabin design, materials, and lighting.

Cons:

- Difficulty: Slower compared to traction elevators. How: Hydraulic elevators may have slower travel speeds, making them less suitable for high-rise buildings.

Technology: Hydraulic systems with a piston and fluid.

Moreover, hydraulic elevators commonly have capacities ranging from approximately 907 to 2,722 kilograms (about 9 to 27 passengers), depending on the design and purpose.

Pneumatic Vacuum Lift Pros and Cons

Pros:

- Unique and modern design.

- No cables or counterweights.

- Pneumatic Vacuum elevators often have limited customization due to their unique design, but options for cabin finishes may be available.

Cons:

- Difficulty: Limited weight capacity. When: Pneumatic elevators may have restrictions on the weight they can carry, limiting their use in certain applications.

- Limited to certain building heights.

Technology: Air pressure changes for vertical movement.

Generally designed for smaller passenger loads, ranging from approximately 454 to 1,361 kilograms (about 1 to 3 passengers).

Machine Room-Less (MRL) Lift Pros, Cons

Pros:

- Space-saving as there is no need for a separate machine room.

- Lower energy consumption.

- MRL elevators may offer customization. So, You can customize in terms of interior design, lighting, and materials.

Cons:

- Difficulty: Higher initial cost. Why: While MRL elevators save space by integrating components, they may have a higher upfront cost compared to traditional traction or hydraulic elevators.

- Limited to certain building heights.

Technology: Integration of machine components within the shaft.

Likewise, similar to traction elevators, machine room-less (MRL) elevators feature capacities ranging from approximately 454 to 2,268 kilograms (about 4 to 23 passengers).

Cable-driven Lift Pros and Cons

Pros:

- Can be geared or gearless for flexibility.

- Smooth operation.

- Customization options can included. So, You can do cabin finishes, lighting, and size to some extent.

Cons:

- Difficulty: Higher initial cost and complex maintenance. Why: Cable-driven elevators, especially gearless systems, may have a higher upfront cost and more intricate maintenance requirements.

Technology: Pulley and cable systems for vertical movement.

Furthermore, capacities can vary widely, with smaller models accommodating around 907 to 2,268 kilograms (about 2 to 5 passengers), and larger models handling more.

Counterweight Lift Pros and Cons

Pros:

- Energy-efficient due to counterbalancing.

- Suitable for various building heights.

- Additionally, It similar to traction elevators, customization options may include cabin design, materials, and lighting.

Cons:

- Difficulty: Higher initial cost. How: Counterweight systems may have a higher upfront cost due to the design and components involved.

Technology: Balancing the elevator car with a counterweight.

Additionally, capacities typically range from approximately 454 to 2,268 kilograms (about 4 to 23 passengers), depending on the design and specifications.

Smart Elevators Pros and Cons

Pros:

- Improved efficiency and performance.

- Enhanced safety features.

- Smart elevators may offer customization in terms of control systems, user interfaces, and integrated technologies.

Cons:

- Difficulty: Higher initial cost and potential cybersecurity concerns. Explanation: Advanced technology features may contribute to a higher upfront cost, and there could be security considerations related to the connectivity of smart systems.

Technology: Integration of sensors, IoT (Internet of Things), and smart control systems.

Moreover, passenger capacity is similar to traditional elevators, ranging from approximately 454 to 2,268 kilograms (about 4 to 23 passengers).

Green or Energy-Efficient Elevators Pros, Cons

Pros:

- Reduced energy consumption.

- Environmentally friendly.

- Customization options are often included. So, You can do energy-efficient lighting, eco-friendly materials, and aesthetic choices as per your needs.

Cons:

- Difficulty: Higher upfront cost. How: Elevators designed for energy efficiency may involve additional technologies, contributing to a higher initial investment.

- Potential limitations in certain applications.

Technology: Regenerative drives, energy-efficient motors, and LED lighting.

Similarly, with passenger capacities similar to traditional elevators, ranging from approximately 454 to 2,268 kilograms (about 4 to 23 passengers).

Freight Elevators Pros and Cons

Pros:

- Designed for heavy loads.

- Durable and robust.

- Customization is often available to meet specific requirements for transporting goods. So, You includes customization in size, weight capacity, and control systems.

Cons:

- Difficulty: Limited passenger comfort. Why: Freight elevators are designed for transporting goods, so they may lack the comfort features found in passenger elevators.

- May require more space.

Technology: Durable construction to handle heavy loads.

Furthermore, designed for transporting goods, with capacities varying widely based on the specific requirements of the application.

Home Lifts Pros and Cons

Pros:

- Provides accessibility in residential settings.

- Customizable design options.

- Home elevators are often customizable. So, You can customize in terms of design, finishes, and size to suit the residential setting.

Cons:

- Difficulty: Higher upfront cost. Explanation: Home elevators may have a higher initial cost compared to other types, considering the customization options and residential design requirements.

- Limited weight capacity.

Technology: Compact designs with residential features.

So, Typically designed for fewer passengers, ranging from approximately 454 to 2,268 kilograms (about 1 to 5 individuals), depending on the model and design.

Glass Elevators Pros and Cons

Pros:

- Offers a scenic view.

- Aesthetic appeal.

- Glass elevators may offer customization in terms of materials, lighting, and aesthetic features.

Cons:

- Higher initial cost.

- Difficulty: Limited privacy. How: Glass elevators, while aesthetically appealing, may compromise passenger privacy due to transparent walls or floors.

Technology: Typically similar to traction or hydraulic systems, with transparent materials.

Moreover, passenger capacities are similar to traditional elevators, ranging from approximately 454 to 2,268 kilograms (about 4 to 23 passengers).

Double-Decker Elevators Pros and Cons

Pros:

- Increased passenger capacity.

- Efficient use of space.

- Customization options may include cabin design, finishes, and technology features.

Cons:

- Difficulty: Limited to specific building designs. Why: Because Double-decker elevators may require specific building configurations, limiting their applicability.

- Higher initial cost.

Technology: Advanced control systems to manage two cabins independently.

Capable of carrying more passengers due to the two stacked cabins, with capacities ranging from approximately 907 to 4,536 kilograms (about 9 to 45 passengers) or more.

Different Types of Lift Price in India

- Here, You know the price range for different types of lifts (elevators) can vary widely based on factors such as the type of elevator, its capacity, features, and the specific requirements of the installation. So, Here’s a general overview of the cost considerations for the mentioned types of lifts

Traction Elevators Price in India

Average Cost from ₹5,00,000 to ₹25,00,000 or more.

Machine Room-Less (MRL) Elevators Price in India

Average Cost of MRL Lift From ₹4 lakhs – ₹18 lakhs

Hydraulic Elevators Cost In India

Average Price from ₹3,00,000 – ₹15,00,000 or more

Cable-driven Elevators Cost In India

Average Cost Starting From: ₹7 lakhs to ₹25 lakhs

Pneumatic Vacuum Elevators Price India

Average Price Range From Minimum ₹9,00,000 to maximum ₹30,00,000

Freight Elevators

Average Price Range From Minimum ₹7,00,000 to maximum ₹30,00,000

Double-Decker Elevators

Price Range in India from ₹15 lakhs to ₹40 lakhs per Unit.

Other types of lifts price India will be varies depending on size, type of glass, and additional features.

So, Average costs, and the actual price can vary depending on several factors like brand, capacity, features, installation complexity, and transportation. Moreover, some providers offer free transportation for shifting the lift to your doorsteps, while others charge for this service. The rate for transportation will vary depending on sellers and lift manufacturers.